Metal Stamping Parts Manufacturer in China

Metal stamping is a mechanical process. As such, it entails the use of machines to perform various processes on sheet metal. However, stamping methods can produce different stamped parts suitable for different industries.

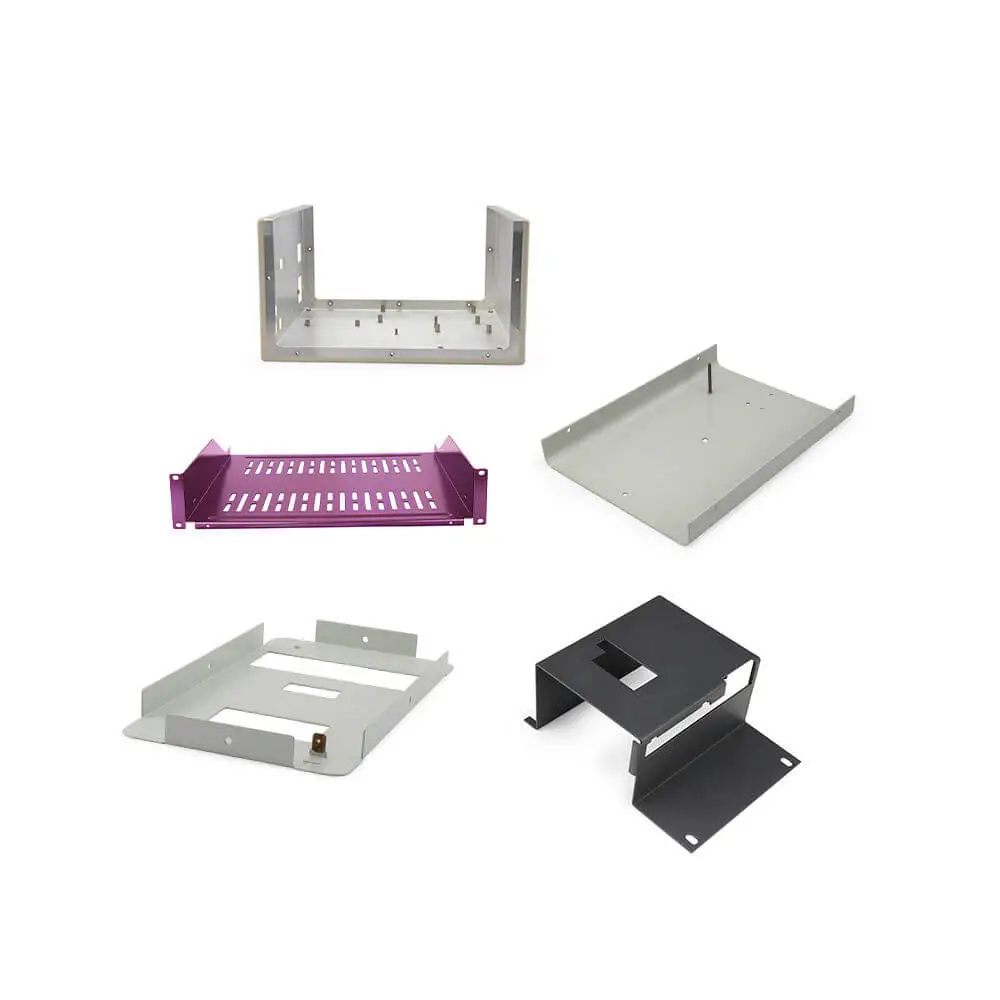

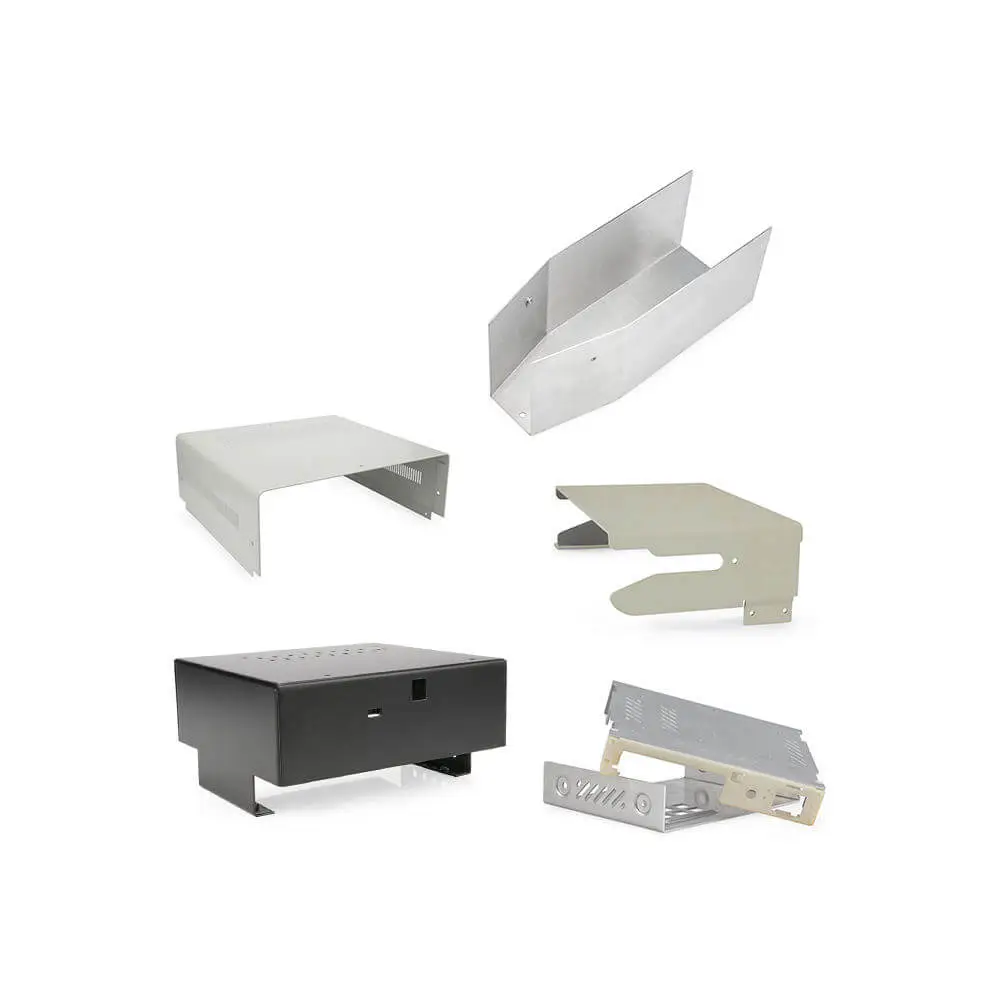

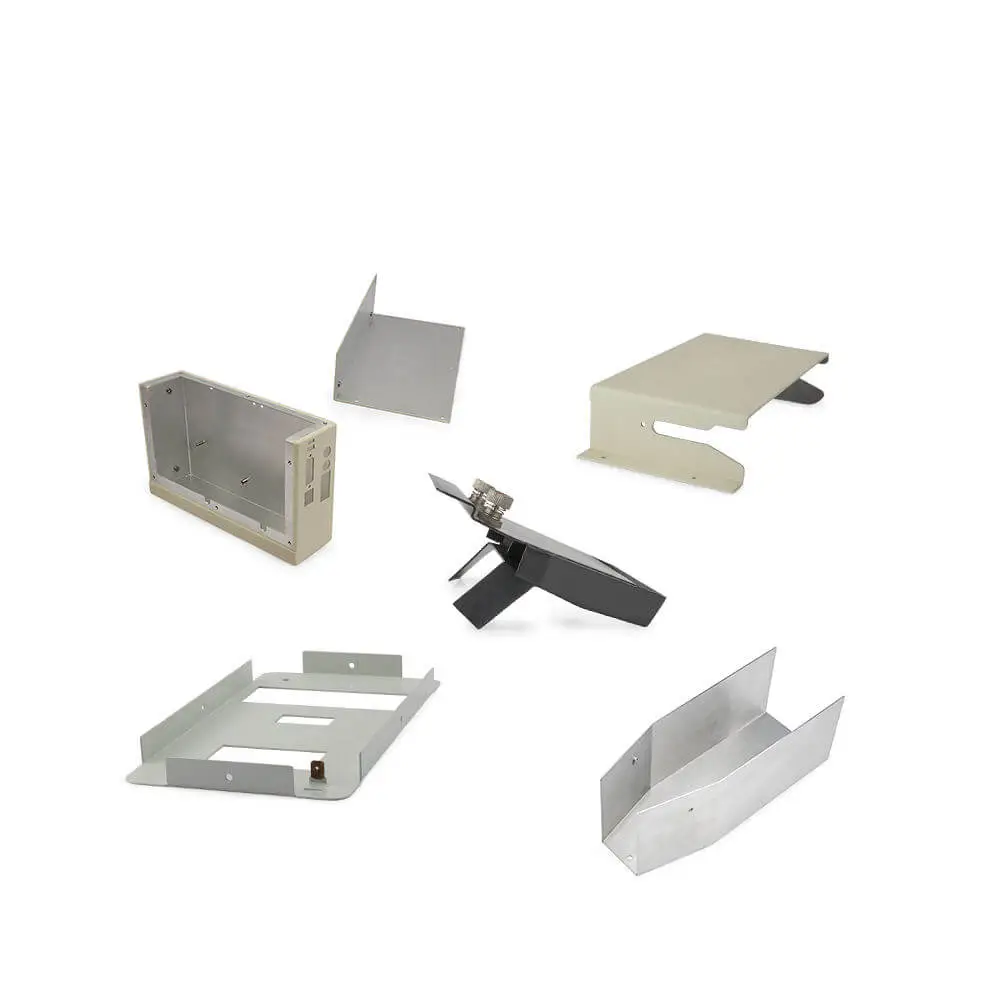

Custom Metal Stamping Parts Manufacturer

The production process of metal stampings is a highly sophisticated and multi-step operation. Each step is critical, from design, material selection and tooling manufacture to the actual stamping, post-processing and quality inspection. By tightly controlling each step of the production process, DYB Stamping is able to produce high quality stamped parts for a variety of industrial and consumer applications.

1. Open the Mould

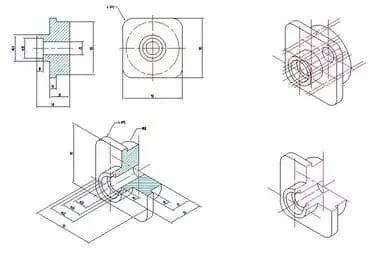

Mould opening is the first and very important step in the production of metal stamping parts. It is a specialised tool used to stamp metal parts and is divided into two parts, the upper die and the lower die, which are mounted on the stamping machine.

During the production process, after installing the stamping die, the metal sheet is placed between the upper and lower dies. The stamping machine is started and the metal plate is stamped into the shape you want.

2. Selection of Materials

In addition to the manufacture of metal stamping dies, the selection of raw materials is also a very important step. Different materials affect the performance, durability and cost of stamping parts. Every metal is suitable for the stamping process.

When choosing a material for your project, you need to consider the material’s strength, special properties and ability to adapt to the environment.

Common raw materials include steel, aluminium and copper. Different metals have their own characteristics, so please select the most suitable metal material according to your project requirements.

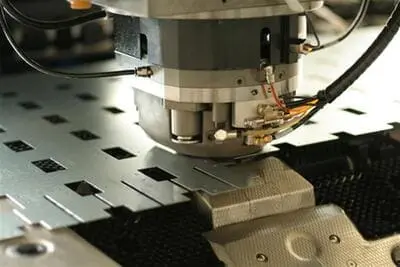

3.Stamping Process

Our factory is stamping design according to your drawing. Metal stamping is generally customised metal parts that are manufactured into the product you need through the stamping process.

During metal stamping, stamping operations generally include the following:

- Blanking

- Bending

- Drawing

- Piercing

- Embossing

Our professional engineers will rationalise the use of different stamping operations to complete your order.

4. Surface Treatment

Metal stamping parts are used in a wide range of different industries, and their use is still very versatile. However, due to the different external environments, some special treatments are needed for their surfaces.

Surface treatment is the last step in the production of metal stamping parts. There are various types of surface treatment, including galvanisation, nickel plating, tin plating and coating. This method can both improve the appearance of the part and add some specific properties.

Custom Metal stamping Parts for Your Project

(1)Fulfilment of design requirements:In complex projects where standard parts may not meet unique design requirements, customised parts can provide a better solution.

DYB Stamping can customise metal stamping parts to your project requirements to exactly match your design drawings and specifications.You can design different shapes, sizes and properties. This is important for your application requirements.

(2)Optimising the use of materials:DYB Stamping can optimise performance and cost for your project by selecting the most suitable material for your specific application.

We offer a wide range of metals including brass, copper, stainless steel, aluminium and carbon steel. Materials are selected based on strength, corrosion resistance, electrical conductivity, weight and other factors. You can choose the material according to your requirements.

(3)Consistent production quality: metal stamping parts are produced using moulds and presses, ensuring that the quality of the parts is consistent. This is essential for projects where quality is important.

(4)Reduced long-term costs: Although the initial design and mould making costs for custom metal stamping parts can be high. However, in high volume production, the stamping process can increase productivity and thus reduce unit costs.

Why Choose DYB Stamping?

DYB Stamping is a first-class metal stamping parts manufacturer and supplier in China, with advanced production machines and excellent staff. We can design, manufacture and deliver your ideal metal stamping parts according to your requirements.

We provide design and development, production, and shipping services to help our customers meet all their needs in a one-stop shop. Our goal is to provide our customers with the best products, quality and value.

- Complete production facilities

- Professional technical engineers

- Strict Quality Testing Process

More Than Just a Metal Stamping Parts Manufacturer

Our timely feedback and support, adherence to high standards, customer-focused solutions and sound advice have cemented our growing reputation. This is because we are always committed to providing a wide range of the best sheet metal solutions to help your business grow.

Metal Stamping Parts Design

We are committed to taking a critical look at our product drawings when it comes to the details of our products. We can customize metal stamping parts to provide the high quality products you want.

Metal Stamping Solutions

Whether you are choosing from our existing metal stamping parts and solutions or want to design something new, we can help you specify a unique and efficient solution.

After-sales Support

We provide perfect after-sales service. We can perfectly help you get the products you want.

Logistical Support

We offer logistic methods that meet your needs. We can help you process and deliver your products on time, within budget.

Frequently Asked Questions About Metal Stamping Parts

What is Metal Stamping ?

Metal Stamping is a manufacturing process in which sheet metal is deformed or sheared into parts of specific shapes and sizes by applying pressure to it. The process typically uses dies and punches to machine sheet or coil metal into a variety of complex shapes. The metal stamping process typically consists of the following seven steps:

- Blanking

- Bending

- Drawing

- Piercing

- Flanging

- Embossing

- Forming

Metal Stamping is an efficient and precise manufacturing method for processing sheet metal into various shapes of parts through stamping, bending and drawing processes. It is widely used in a variety of industries and is favored for its high productivity, precision, and cost-effectiveness. Through the use of specialized dies and presses, the metal stamping process is able to produce a large number of complex, precision parts to meet a variety of industrial needs.

Prons of Metal Stamping

- Efficient production: metal stamping allows for mass production and is particularly suited to the manufacture of a large number of identical parts.

- High precision: through precision molds, parts with complex shapes and precise dimensions can be produced.

- High material utilization: the stamping process can maximize the use of materials and reduce waste.

- Wide range of application: It is applicable to various metal materials, such as steel, stainless steel, aluminum and copper.

- Cost-effective: for high volume production, the stamping process has a low unit cost.

Applications of Metal Stamping

- Automotive industry: for the manufacture of body panels, chassis components, engine parts, etc.

- Aerospace: used to manufacture aircraft structural parts, wing components and cabin fittings.

- Electronics: used to manufacture cell phone housings, computer parts, connectors, etc.

- Home appliance industry: for the manufacture of washing machines, refrigerators, microwave ovens and other equipment shell and internal parts.

- Construction industry: used to manufacture metal roofs, wall panels, window frames and other building materials.

How Dose Metal Stamping Work?

The basic principle of metal stamping is that a flat sheet of metal is deformed or sheared in a die by applying pressure through a stamping press to form the desired part. The die determines the final shape of the part, and the press provides the necessary pressure to complete the process.

Metal stamping is able to efficiently process sheet metal into a variety of complex shapes and sizes through the collaboration of a die and a press. This process is suitable for mass production. It also has the advantages of high precision, low cost and high material utilization. Through precise mold design and strict quality control, metal stamping is able to meet a wide range of industrial needs and provide high-quality parts.

Any Other Questions? Ask Our Experts

The final production of metal stamping parts is a complex process. It requires design, control and production. A new metal stamping parts usually involves a large investment upfront. If you have questions about metal stamping parts, please contact us. We have design and manufacturing experts who can help you.